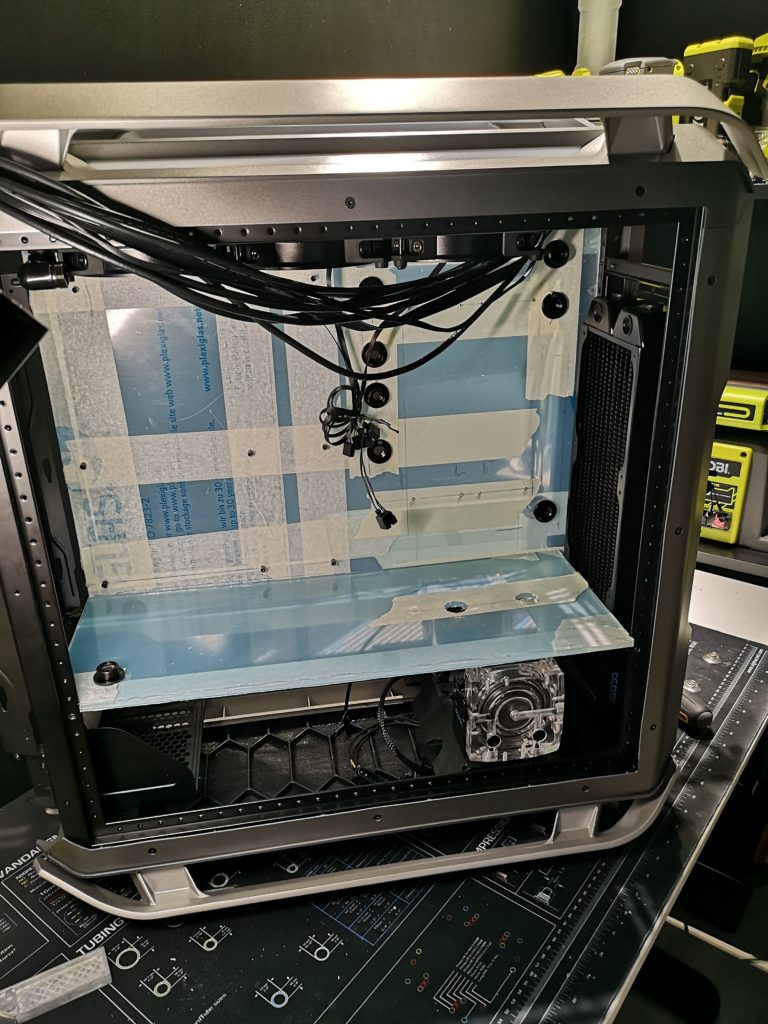

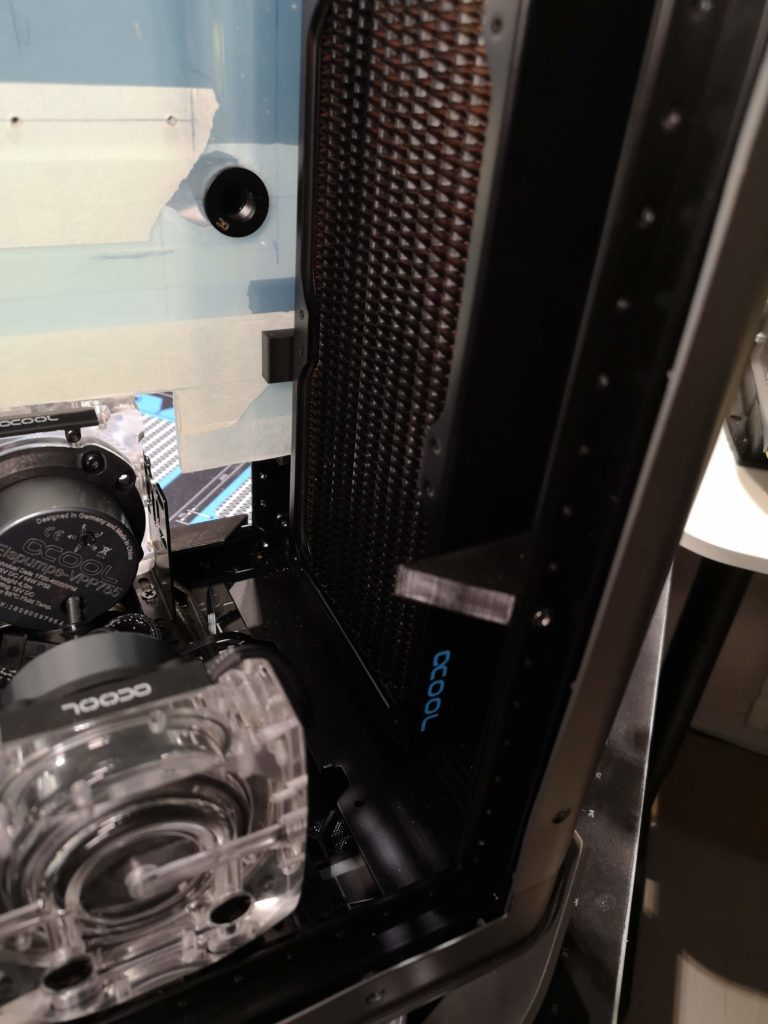

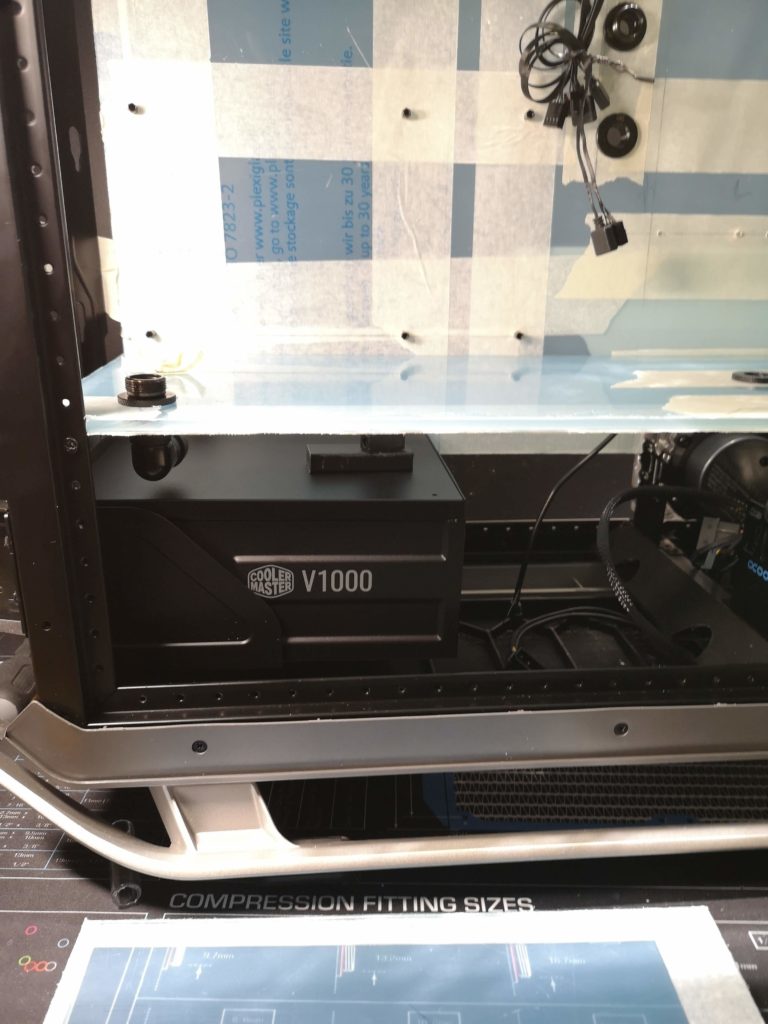

PSU shroud was up on the agenda. With part of the hard tubes done for the loop I need to connect the loop into the PSU shroud. More precision drilled pass throughs

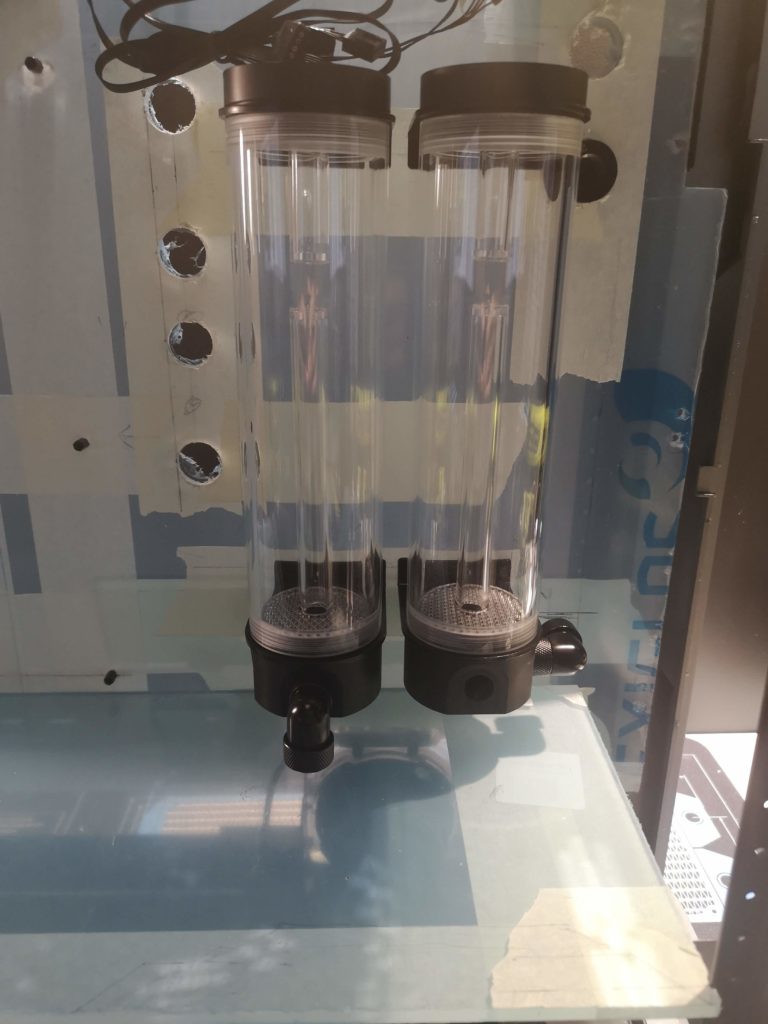

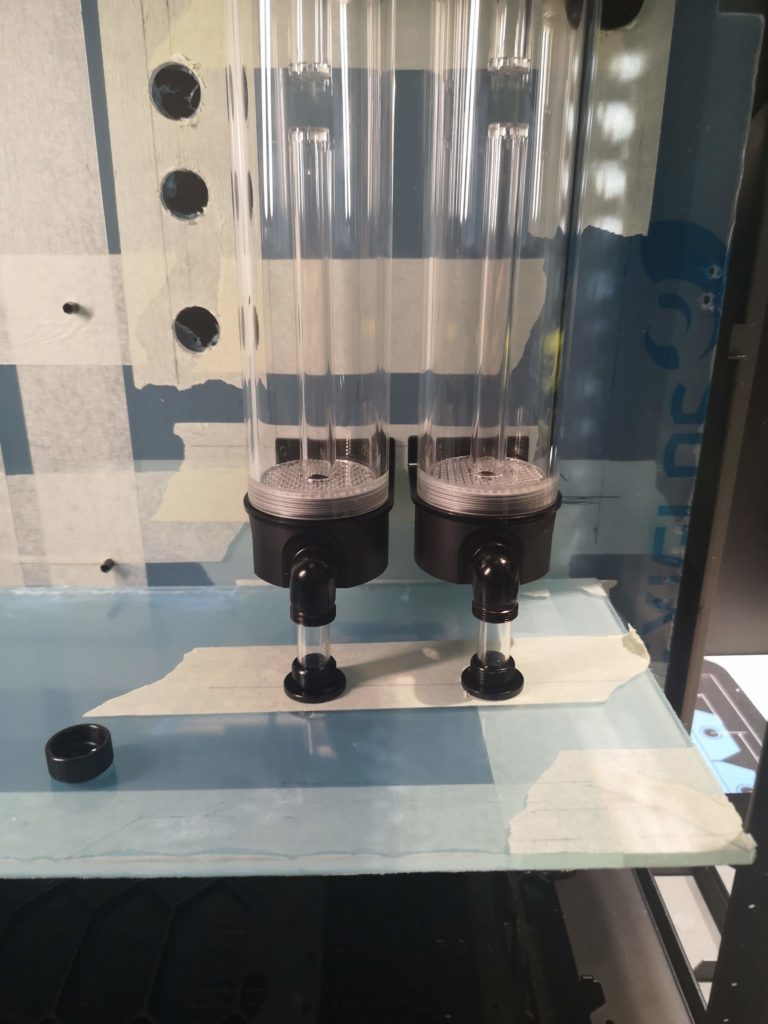

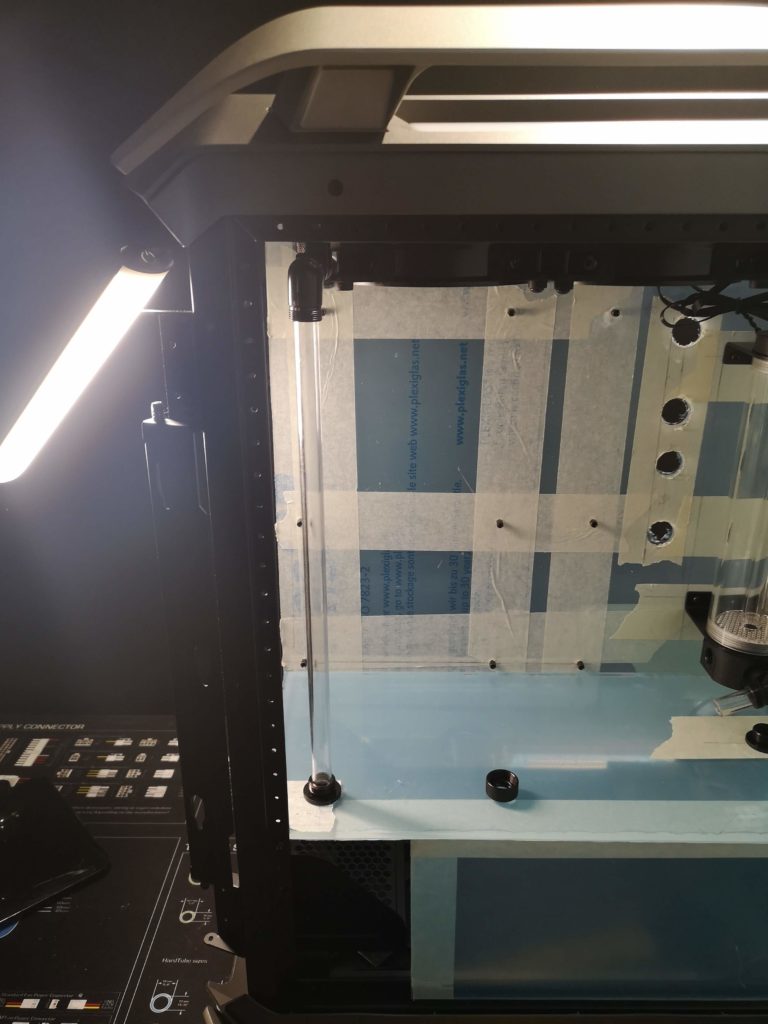

As it was time to mount the reservoirs to make those connection I also took some photos. Love the feel of acrylic and glass.

That’s how I will mount them. Changing my straw-loop a little, but to the better.

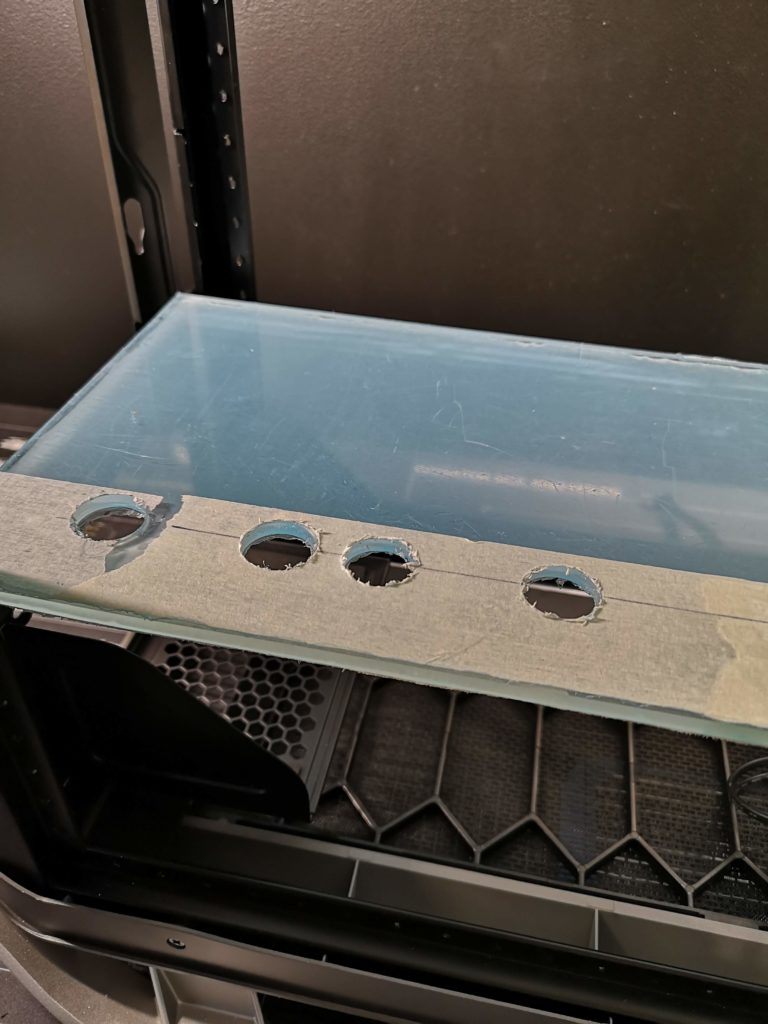

Two quick holes with my stepdrill and ready to continue.

Much better. Small tubes, but enough to show some colant going into the shroud.

Like that

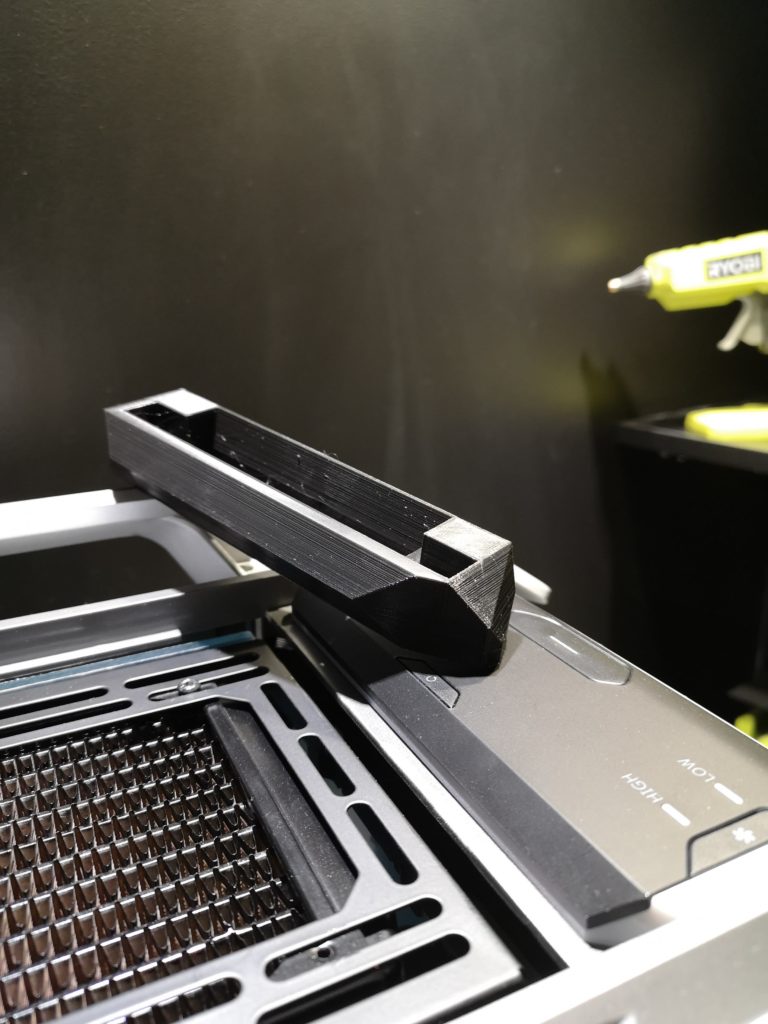

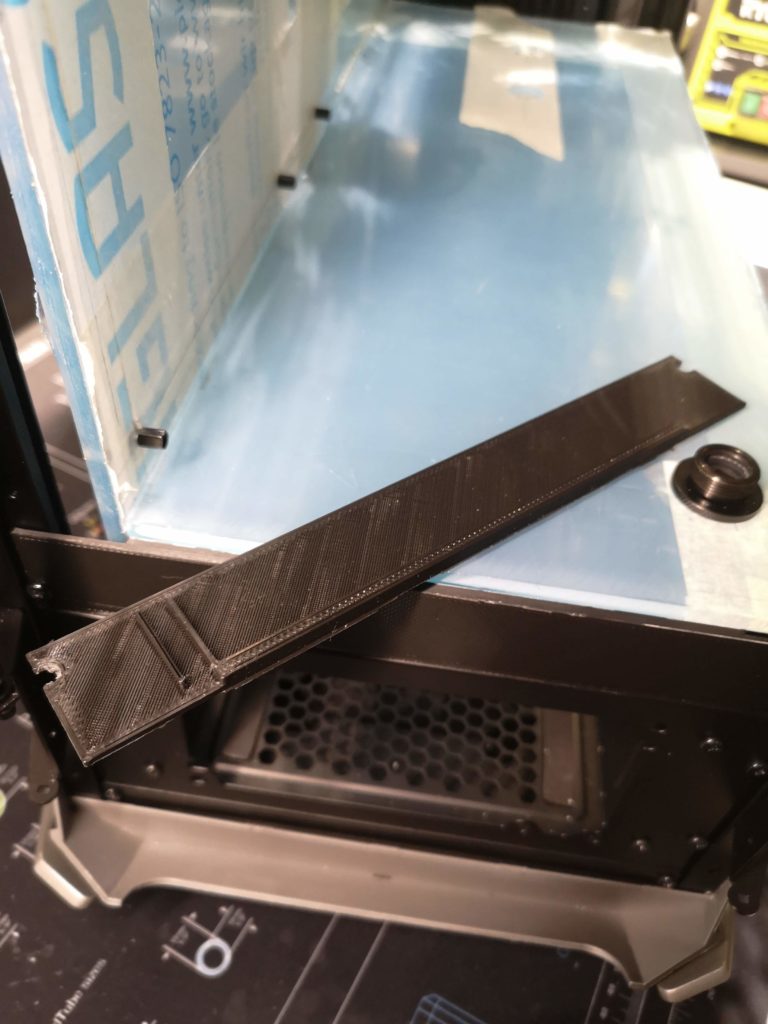

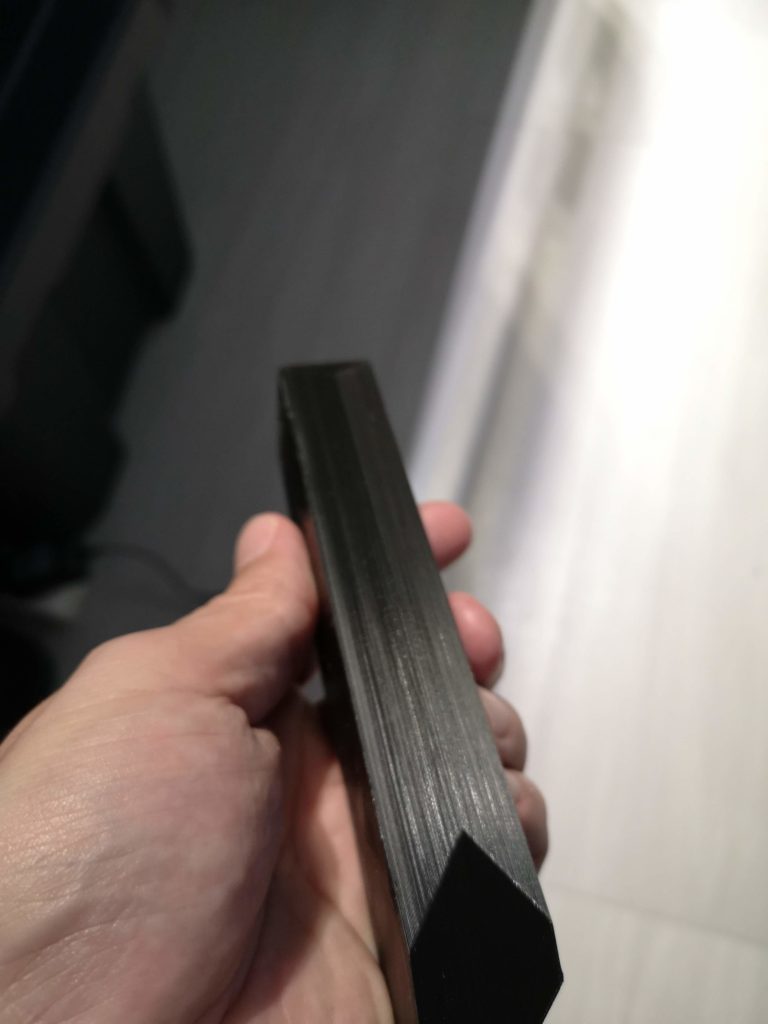

This will be a GPU bracket that I will mount ontop of the shroud. It has both screw holes for the riser cable and below that screws for the shroud. Angles are them also fetched from the angle of the exterior of the case. Should harmonize well.

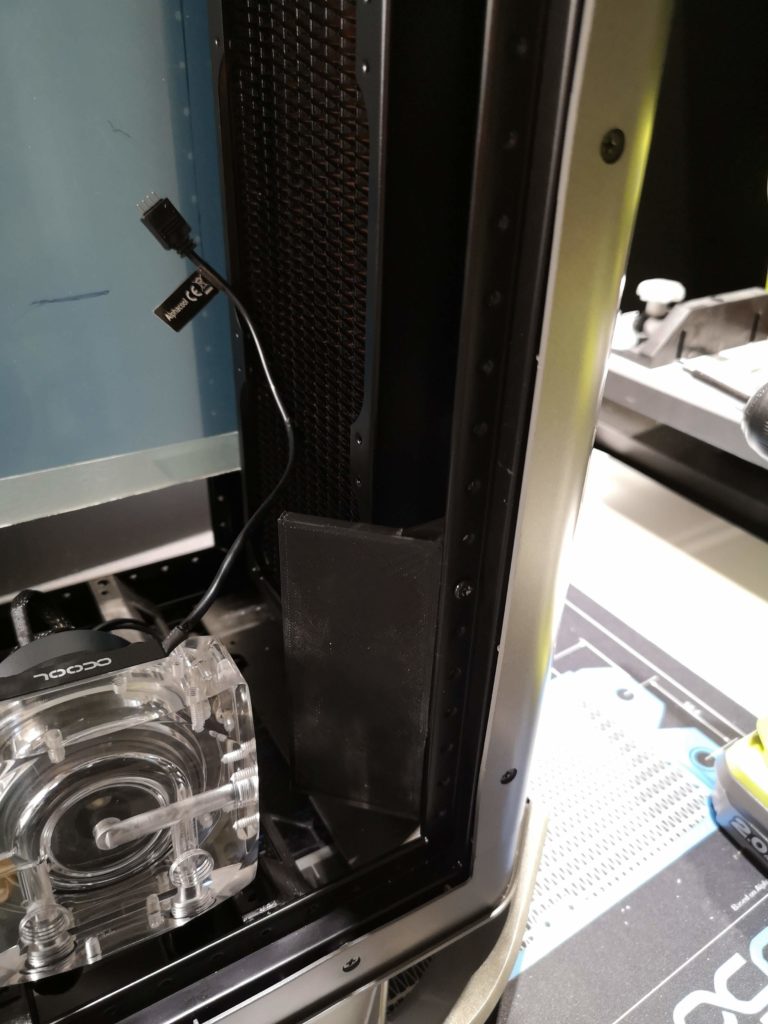

With the bracket decided I could move on with the corner pass through from the radiator above.

Nothing strange. A straight tube.

Did a quick test with the PSU. This is the main reason for my previous comments about why I wanted the PSU Shroud exactly 130mm up. I need to fit the fittings That will go straight out to the backside.

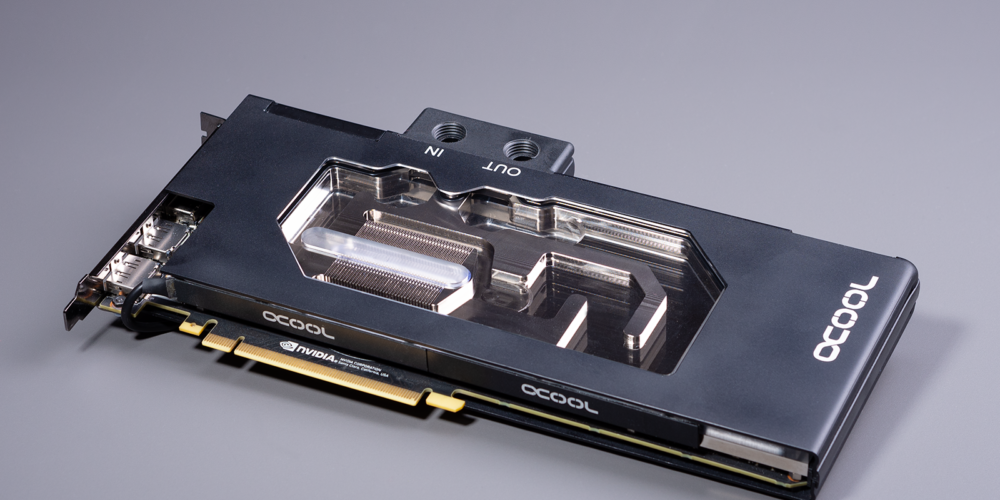

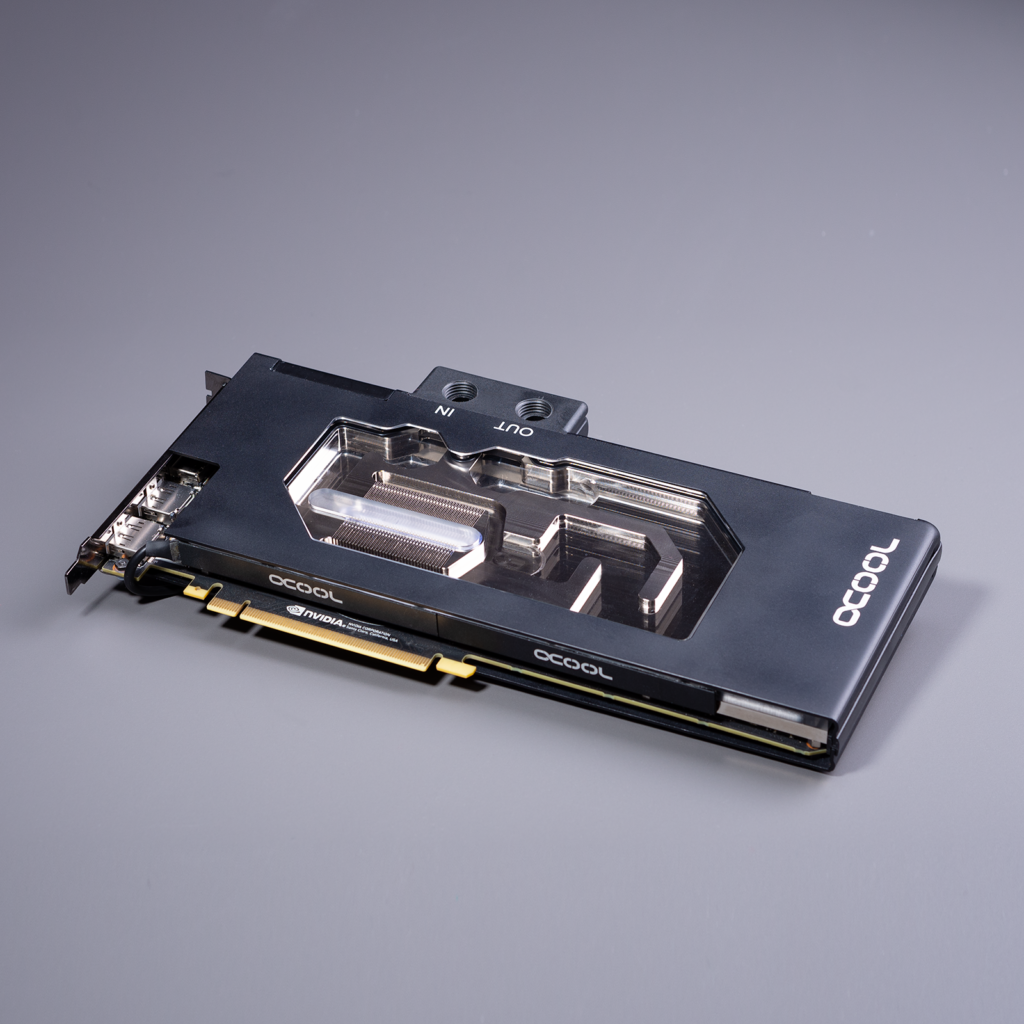

Spent about an hour, with elevated pulse, adding the waterblock to my 1080Ti. That will be perfect. That also passed infront of my camera.

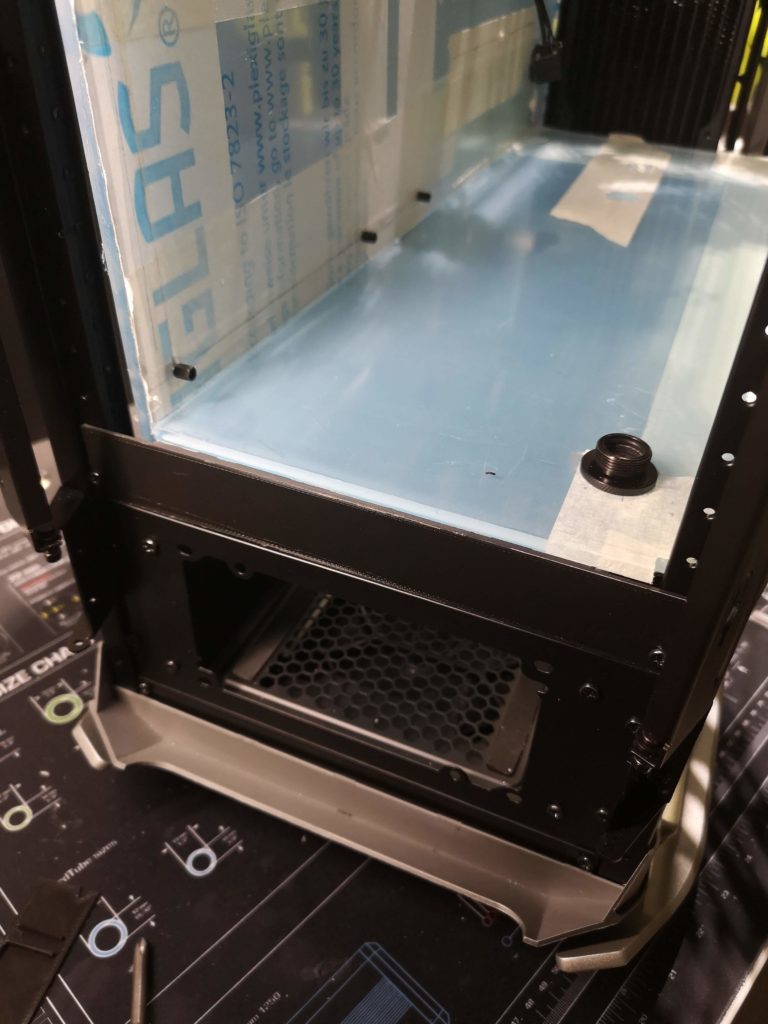

With the waterblock on the GPU I could make measurements for the GPU pass throughs. Thoose two will also “drive” the location of the final pass through. But first I wasn’t happy with the shroud brackets or the obvious problem of adding 1kg+ of weight ontop of a thin acrylic sheet. The sag is real…

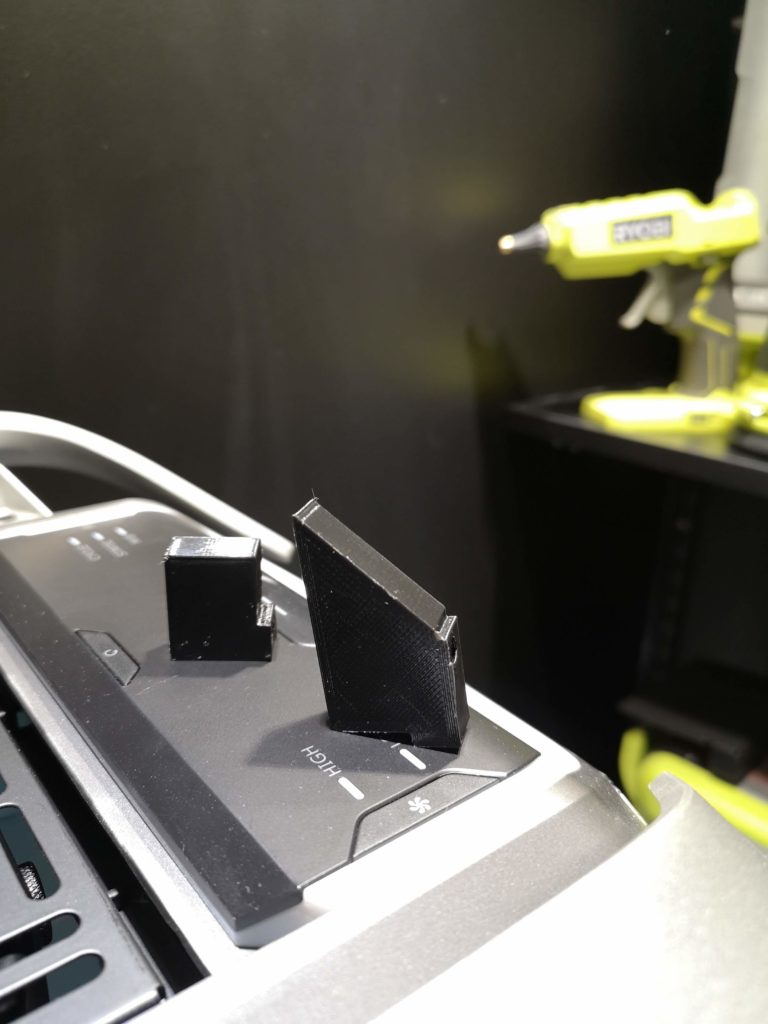

Redesigned the MB bracket from the backside and did a simular solution for the PSU. But this time also with a 45deg angle to support the upcoming “wall” for the pump enclosure.

Added a bracket to use in the front, to support the back corner of the PSU

Just two standard case screws from the front (making it adjustable in height) and I felt I had a nice solution for the shroud.

Made a planned update to the back bracket (that will be much bigger and include holes for GPU, PCI slots etc). It also has a vertical slot to guide the motherboard plate. As it’s isn’t the finished plate it’s printed on prototype profile (fast) making it look bad, but printing/modding quicker.

Much better. That secures the PSU shroud plate, but doesn’t take care of the sag.

It’s not a permanent solution, but will take care of the support of the GPU for now.

12h later and after 2h of sanding I had a new GPU bracket. This time with an integrated holder for the lower part of the PCI bracket. It’s not finished, only sanded with 240, 320 and 400 at this point, but already smooth

Compared to no sanding.

With the real GPU bracket I could ensure I had the right location and placement compared to the back.

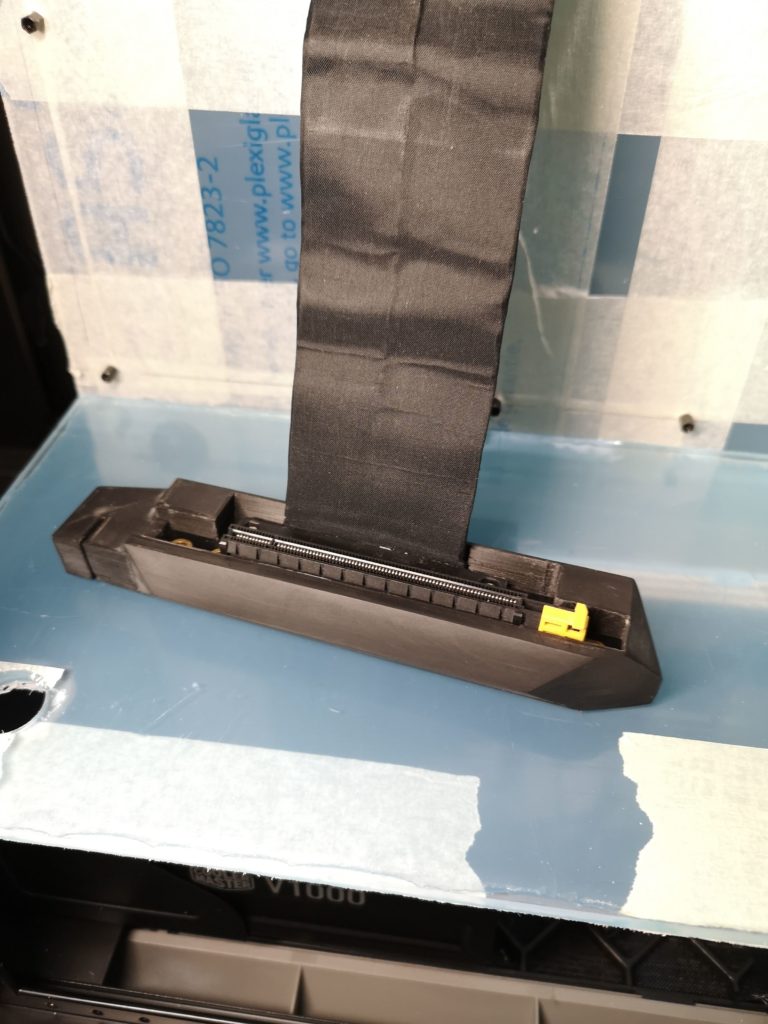

Testfitted the riser cable, added the GPU and took measurements for the final pass through holes.

Voila! Starting to feel like a real build. 14 out of the 16 pass throughs hand drilled and in the right place. Tomorrow I will continue with finishing the backside holes and bend some tubes.