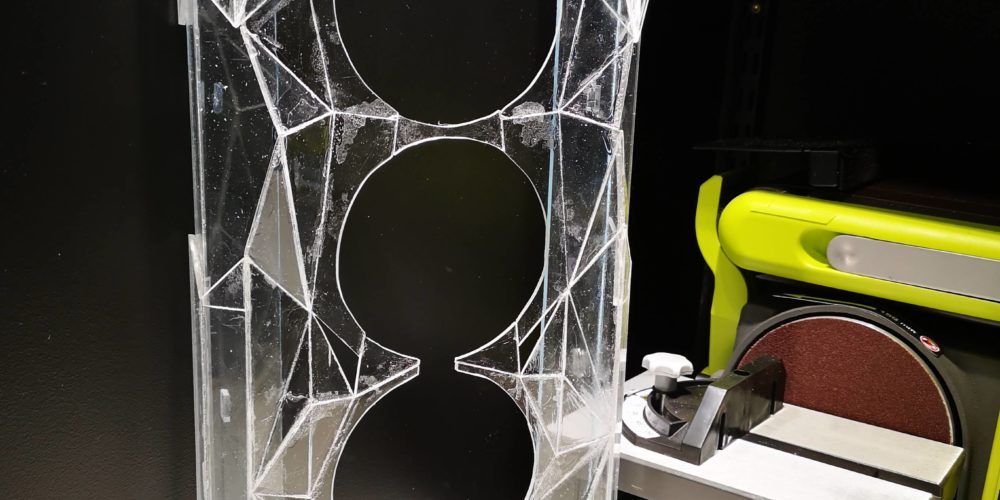

After a new modding room and a full stack of amazing tools thx to Ryobi I could get back to modding and project Angl3d Ti. Some parts left to do on the complicated front as well as closing up the bottom and front.

It was suddenly a dream. The last 3 angles to finish the front took 20min to finish instead of 200min. The saw and sander from Ryobi are monsters. Surprisingly quiet, but so powerful.

This is the last problem area left to do. Joining the bottom piece with the front piece.

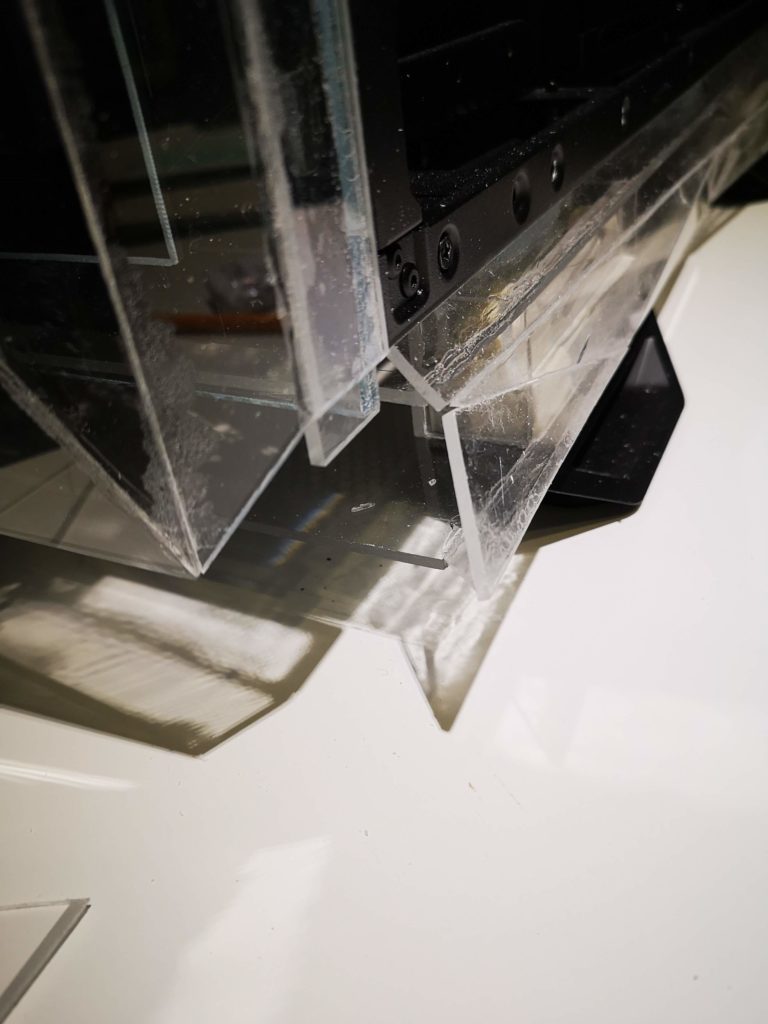

Fast work at the new saw and some sanding

And we had a match. Left the piece a little big by choice, need to file it into perfect size to ensure an unvisible joint with the front.

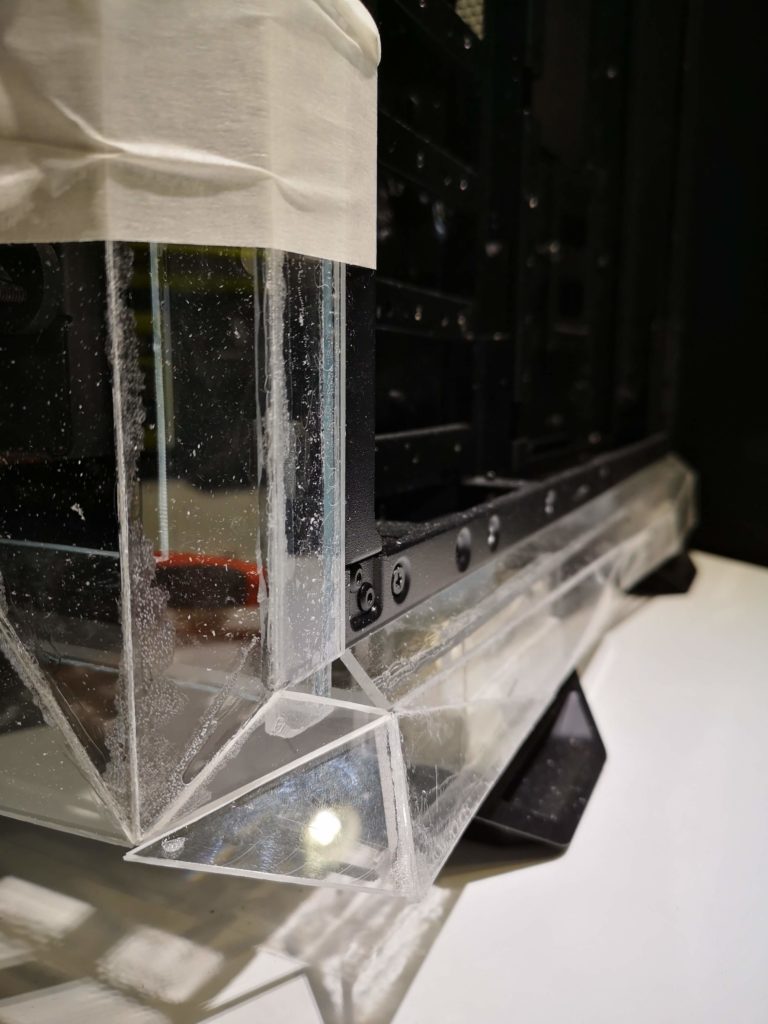

Two larger pieces was all that was left to close up the bottom.

One final test fit before I added the pieces to the bottom. Then I will have to spend a few days sanding…

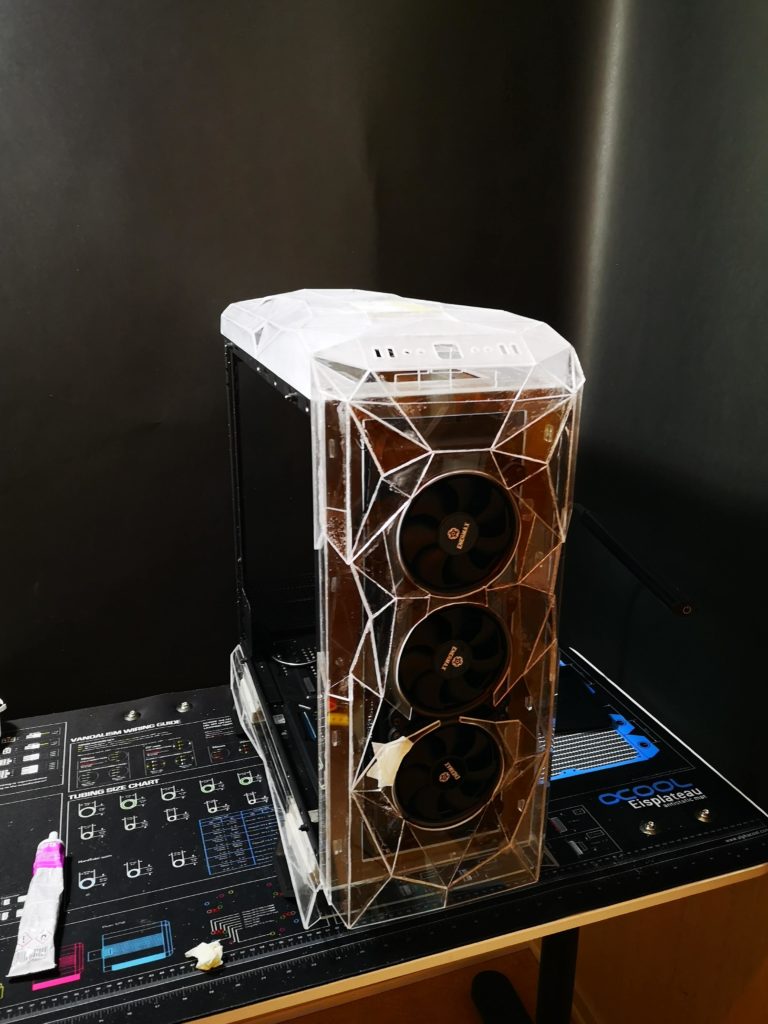

I spend almost the next week finishing up the 3 pieces. Just not sanding, but filling in all small gaps and uneven surfaces. The large beige section is plastic wood. Had to make up for a less perfect piece, but now it’s even and smooth.

Will be so much fun turning this into black matt finish. Exterior is close to finish. Probably got 2 weeks left, sanding down the 3 front holes to perfect shape and size and then desining and 3D-print all the mesh pieces. Need to learn how to print and design…