Very excited about starting the inside of the case. It has been a long time since I did the PSU Shroud for project Angl3d and feels extra special to start to build around it.

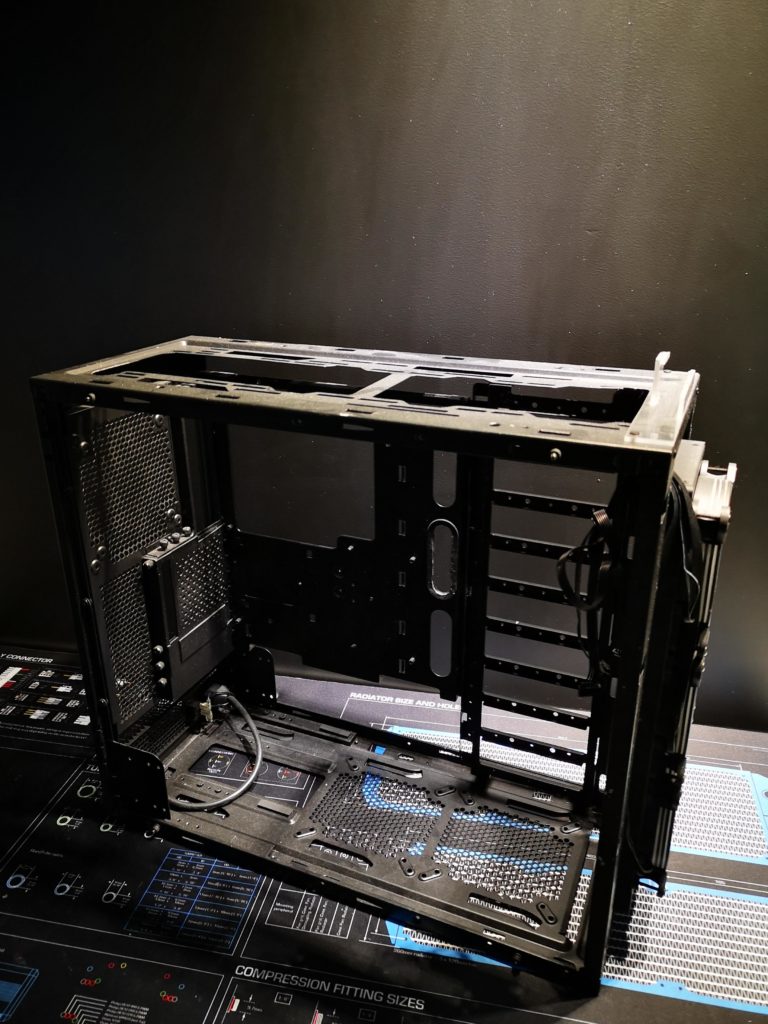

It’s a beautiful case, the be quiet! Dark Base Pro 900, even without it’s amazing exterior. Love the removeable backside, MB tray solution.

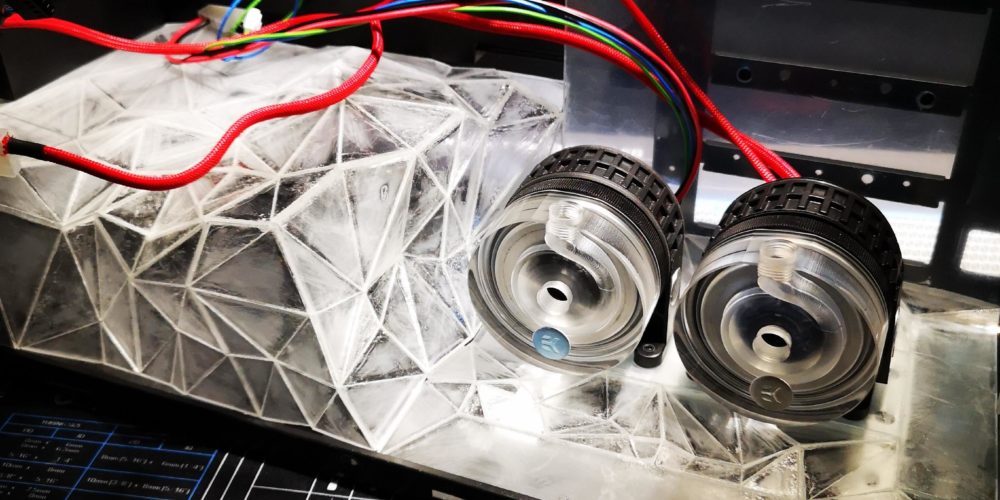

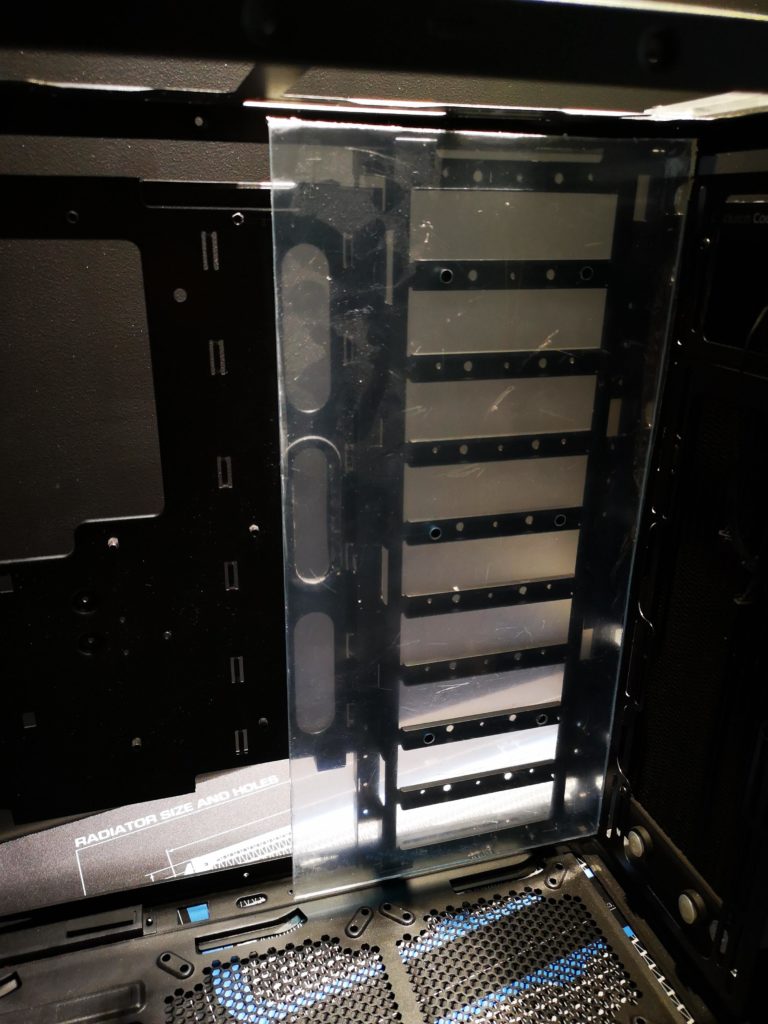

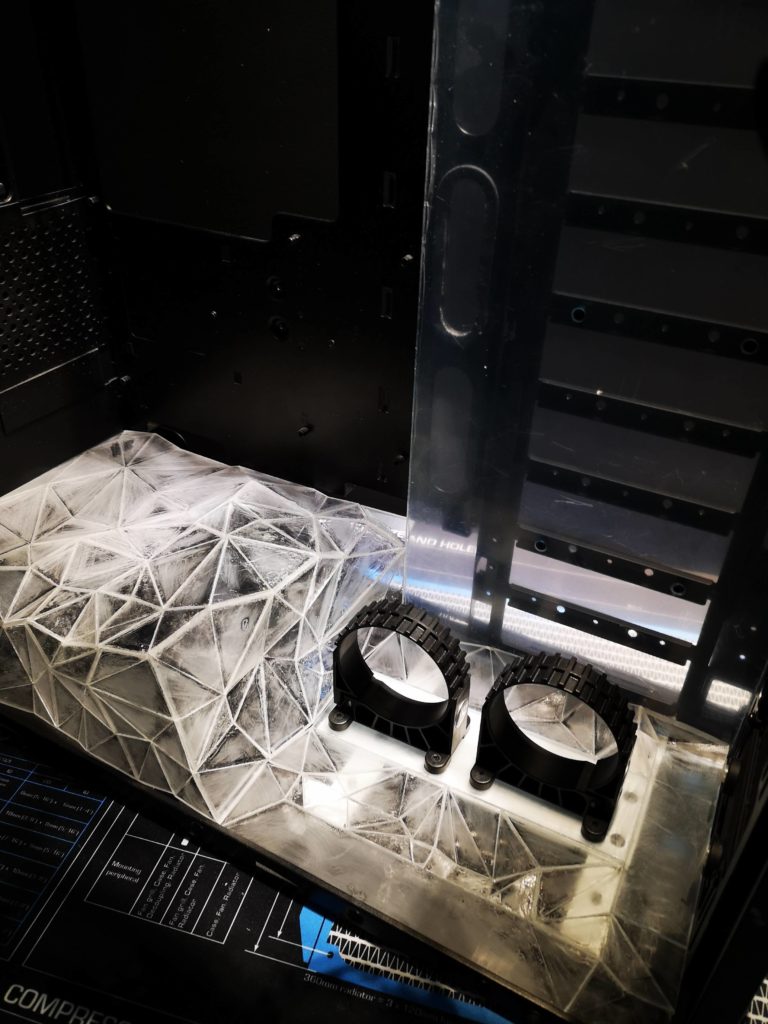

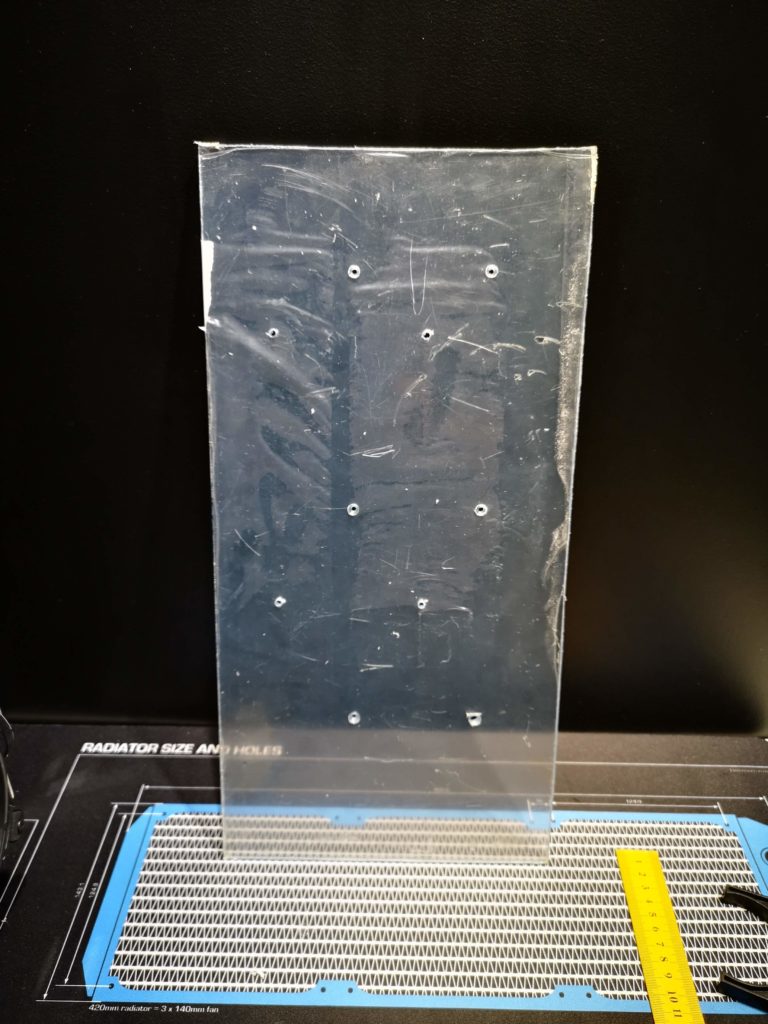

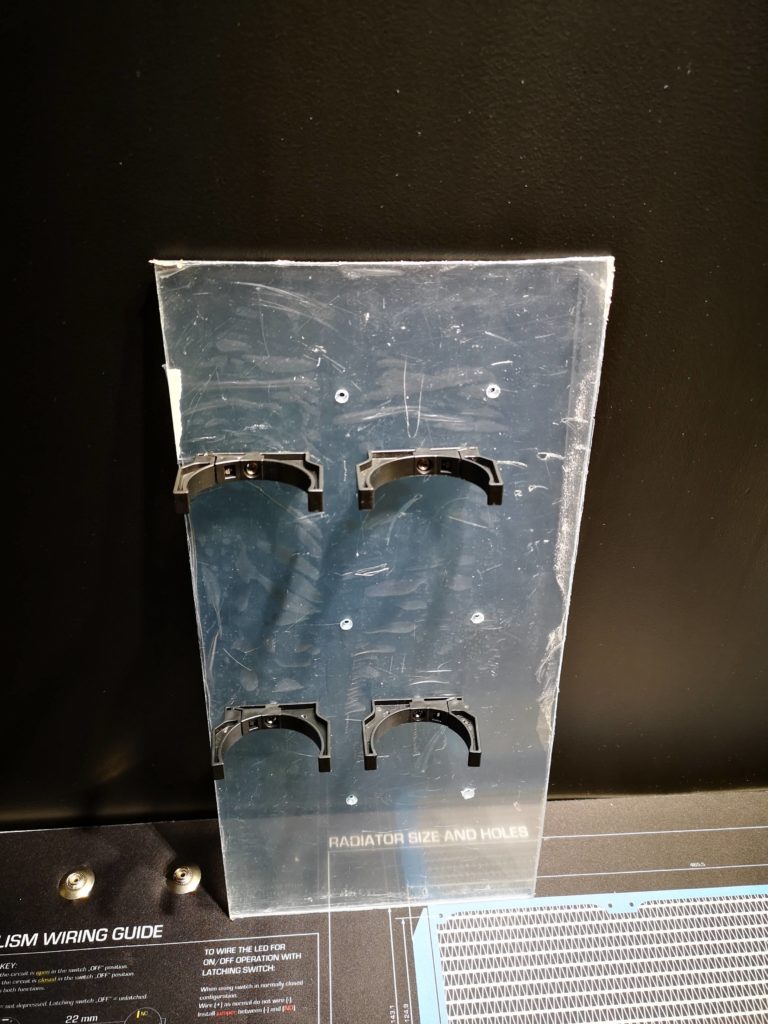

Started by cutting a backdrop mounting plate in 3mm plexi for the dual EKWB RGB reservoirs.

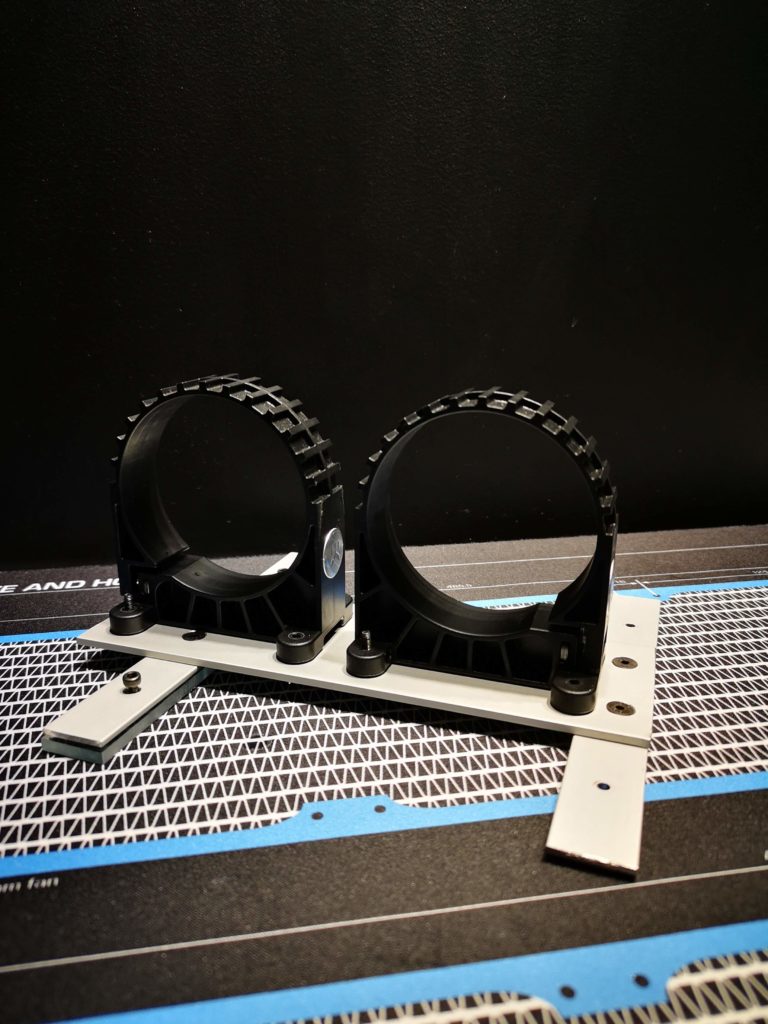

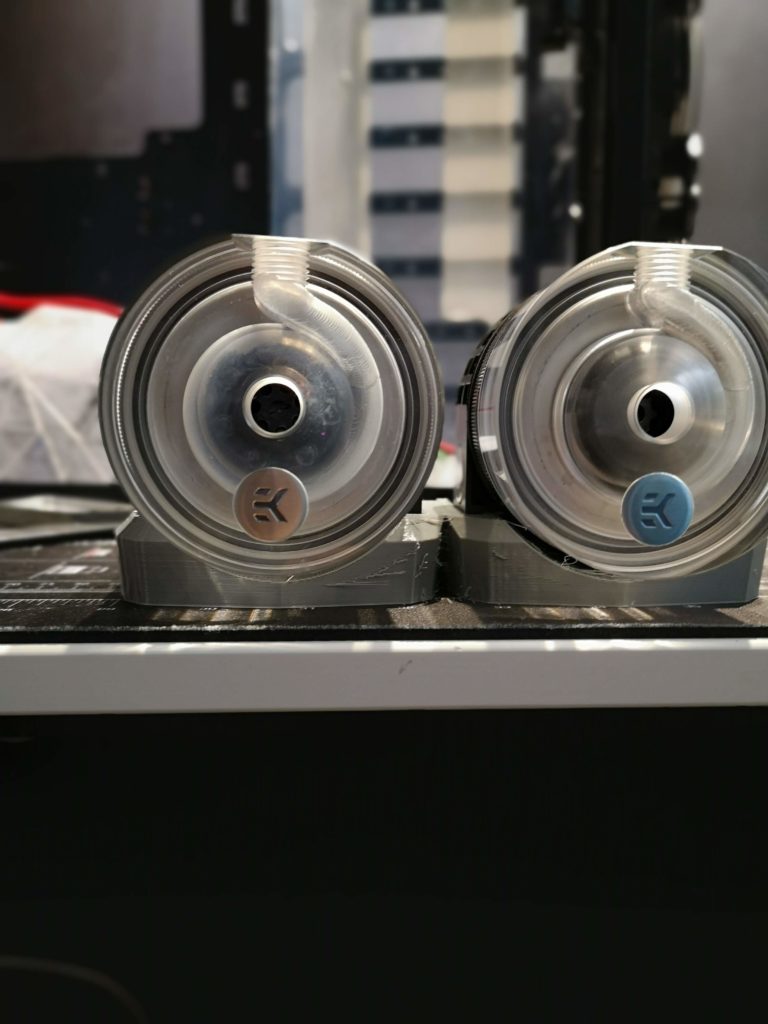

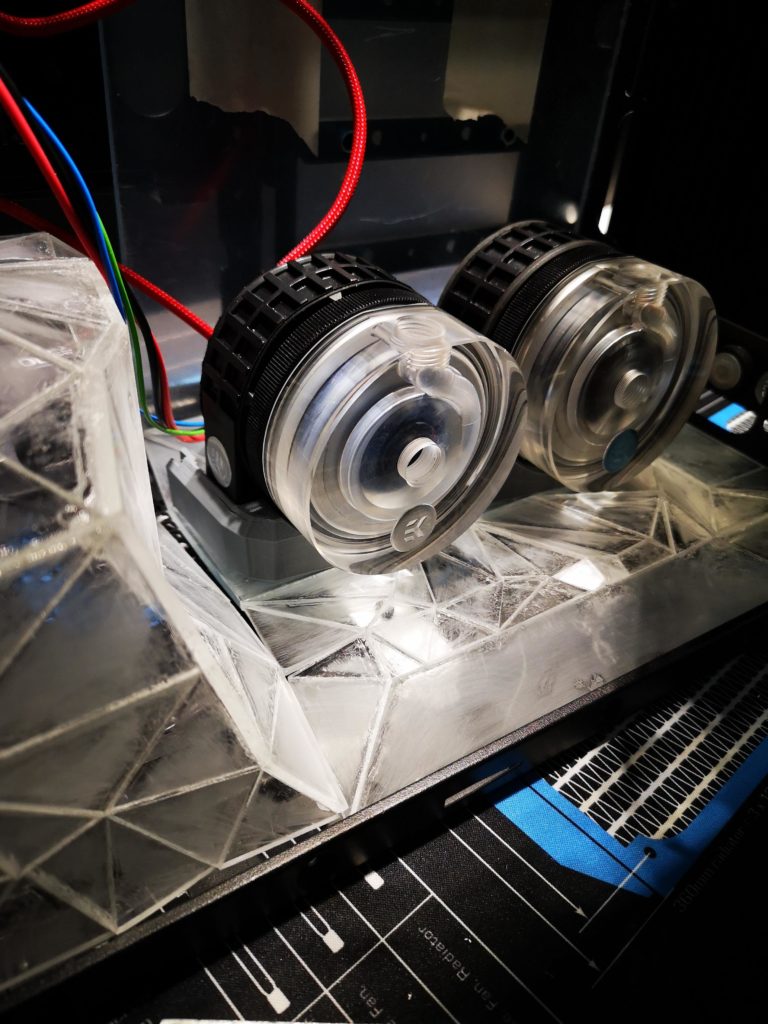

Installed the previously created custom EKWB D5 dual pump bracket.

The lower part of the custom PSU shroud still fits perfectly and was snug against the reservoir backplate. But I wasn’t happy with the holes for the pump brackets. One side was off with almost 2mm.

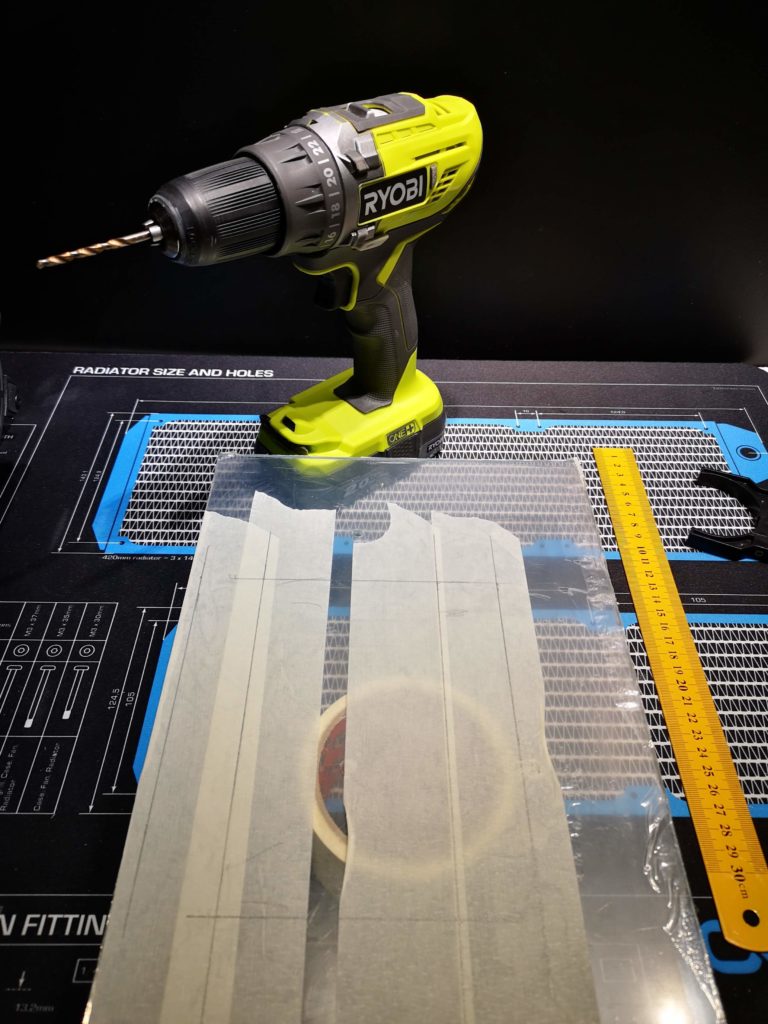

Nothing my new Ryobi can’t fix. Took a 3mm drill and expanded the holes that was off.

That’s what I’m talking about. A much better fit.

Looks really good and scary tight. It will fit, I know that, but still can’t help worring a little…

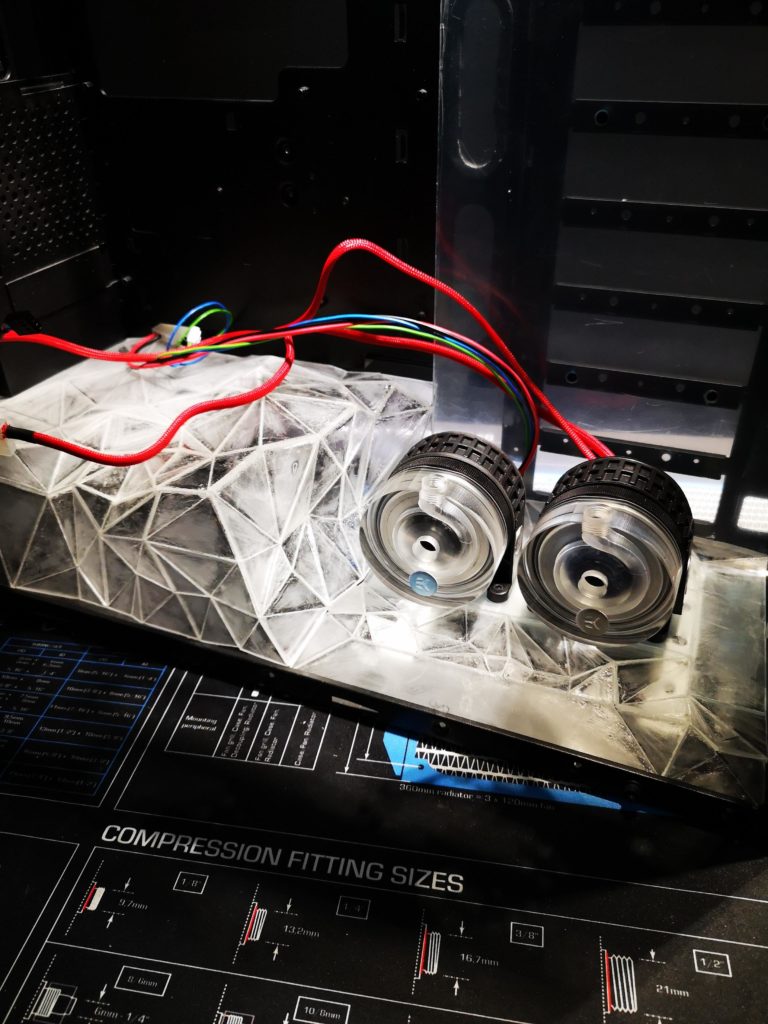

The combination of hard edges of the PSU Shroud polygons with the soft and beautiful roundness of the EKWB D5 plexi tops is just stunning. Can’t imagin how ace this will look when the shroud is coated in matte black.

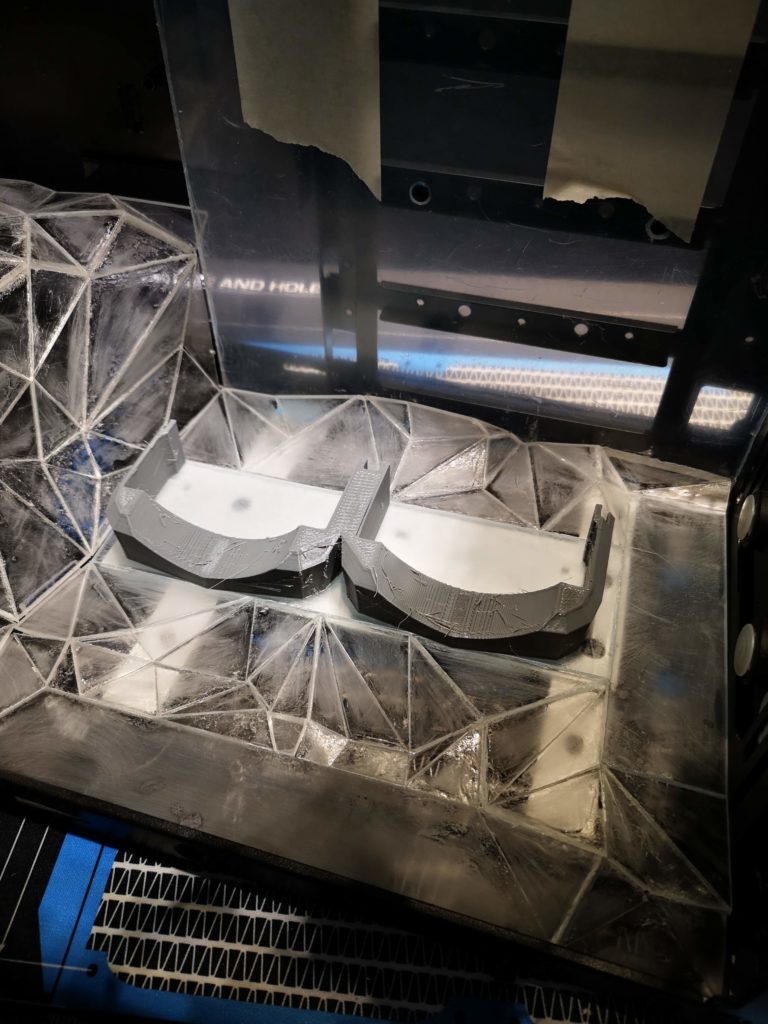

Redesigned the pump-bracket base into a single dual unit. Clearing the PSU shroud with 1,5mm…

It’s not a very bid differance, but still believe the little heavier base this 3D printed detail will add to the mod. Slightly angled outwards and angled corners.

For thoose of you that just turned into this log, it’s still just printed with a prototype profile, hence the poor quality. The dual bracket is less than 1 hour print and with final profile almost 4h, so will look better 😉 Also printing with high quality Swedish black matte filament from add:north for final prints.

Still very proud of the PSU shroud. It will make the beautiful and round water cooling products from EKWB to pop.

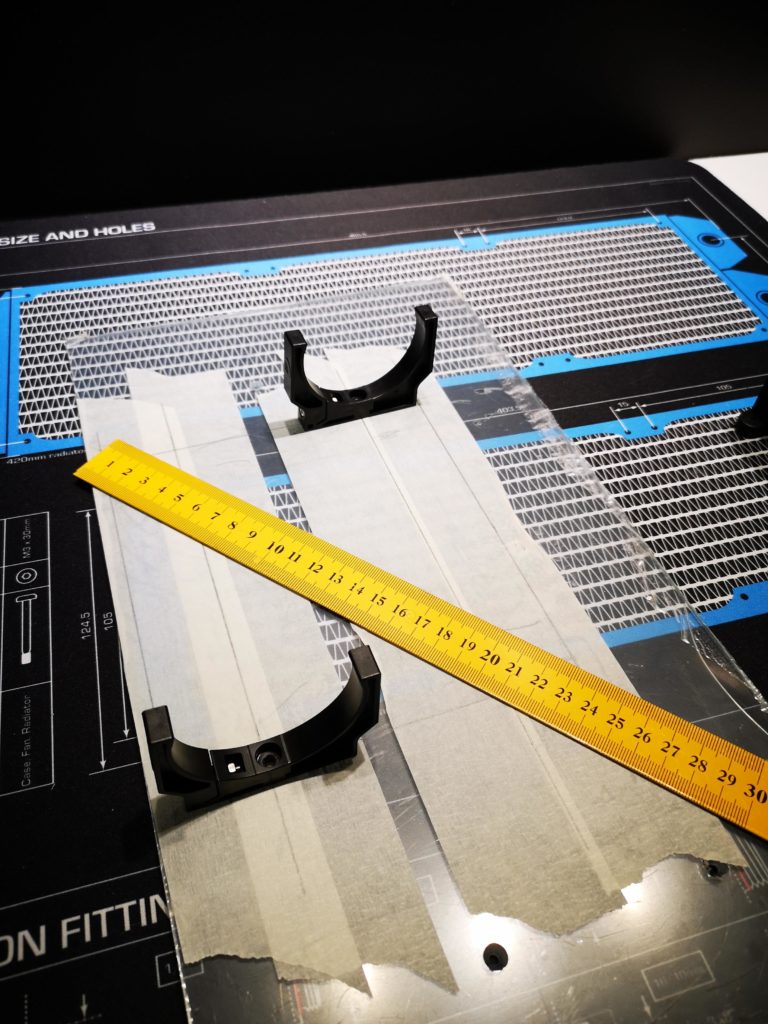

Nope, not very clean, but still very ace 😉 using for measurements.

Spent a little time adjusting and measuring between the dual pumps, placement of the reservoirs and the GPU. Decided to make a very unconventional mounting of the GPU that will make the placement of the dual reservoirs better. Centered placement over the pumps.

Drilled out 4 holes for the reservoirs and another 6 holes for mounting the backplate to the HDD ladder.

With a full box of a few thousand of countersunk M3, M4, M5 and M6 bolts I couldn’t resist making the mounting holes countersunk with a plan for exposing the bolt heads. Color coordinated 🙂

Leaving room on the right side for hard tubing, fittings and other fun stuff.