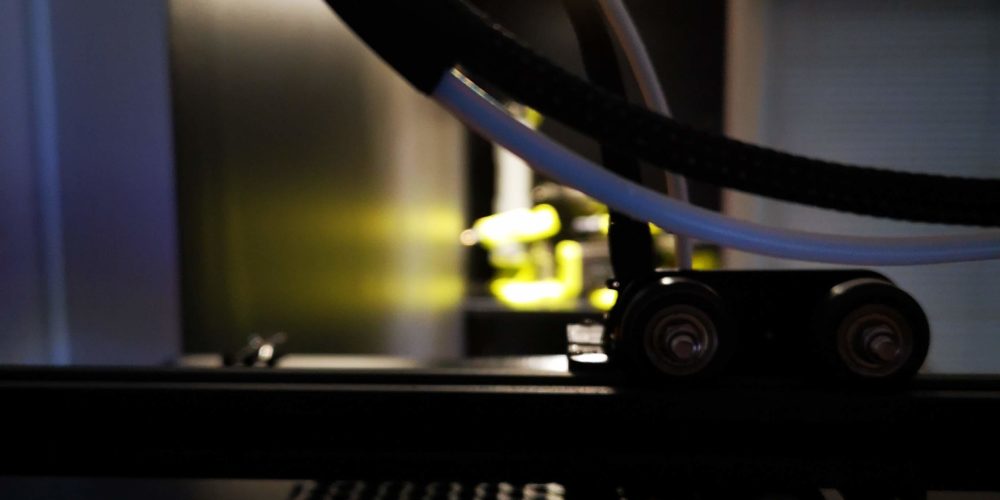

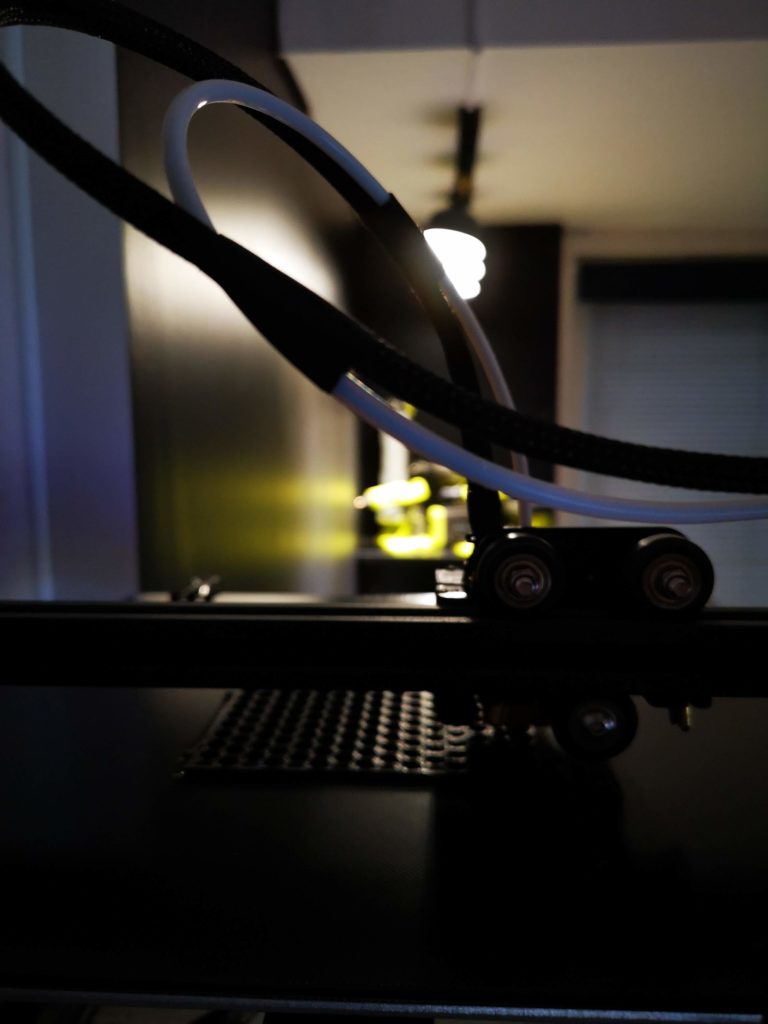

It has been a time consuming and fairly tough period to dail in my 3D printer to the level I require, but once done the parts started to roll out the plate. Printed almost 24/7 for the last 3 weeks.

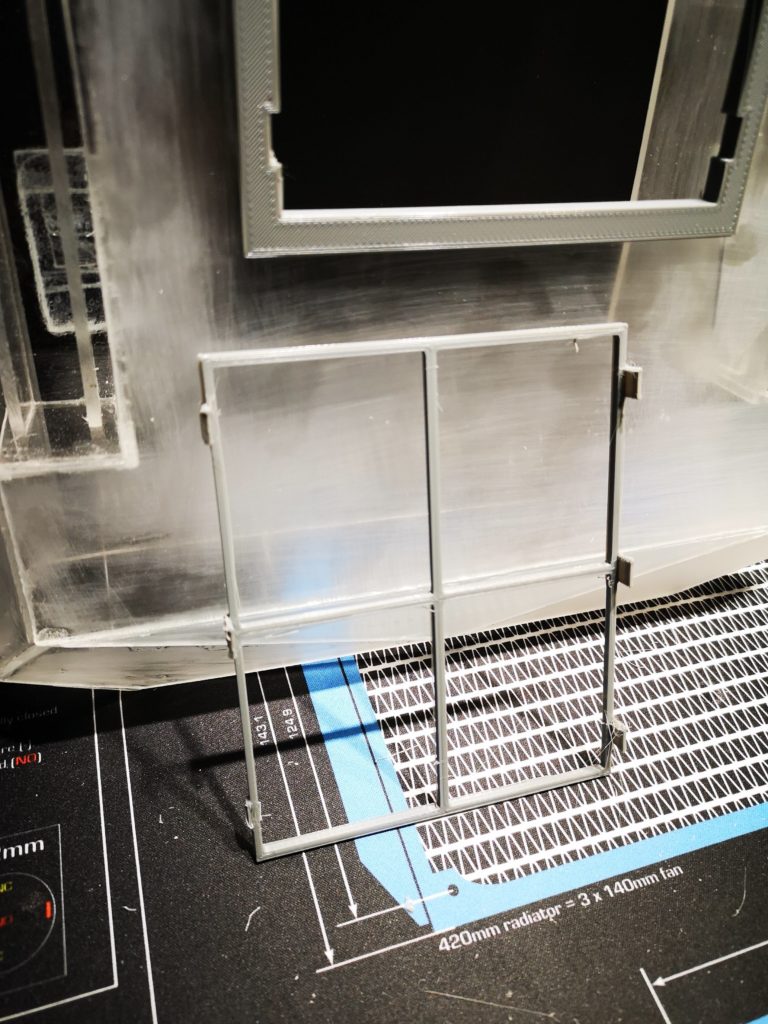

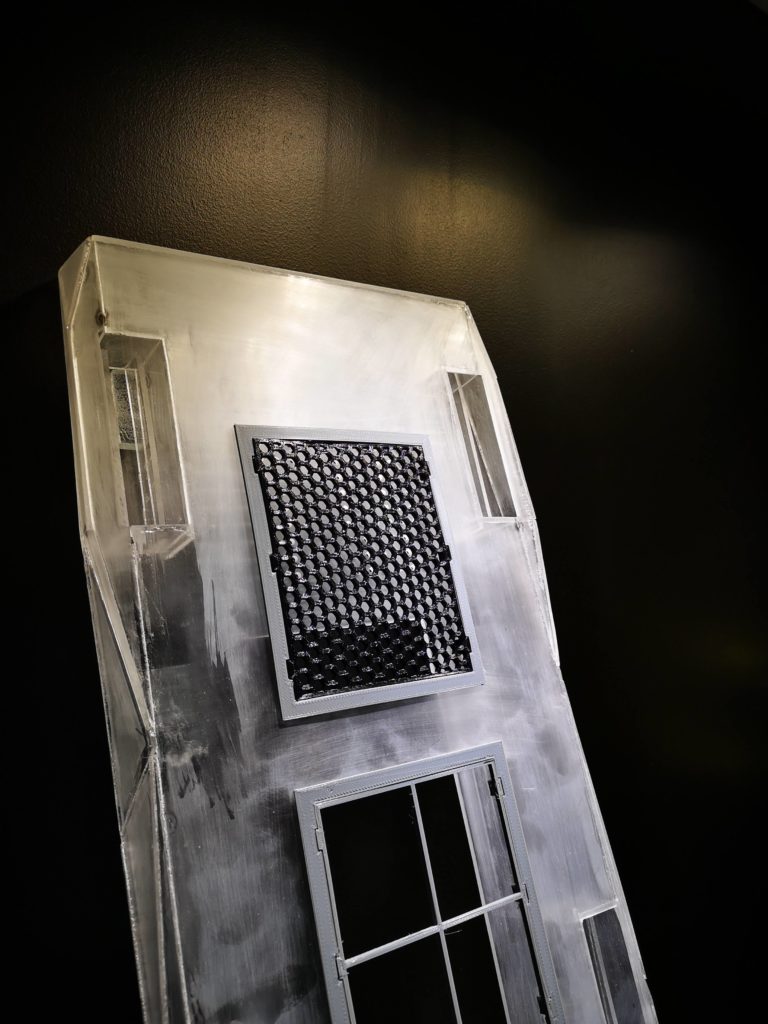

After a few adjustments and attempts I got the design I wanted. Opted for a frame that I then will design and clip an air intake cover.

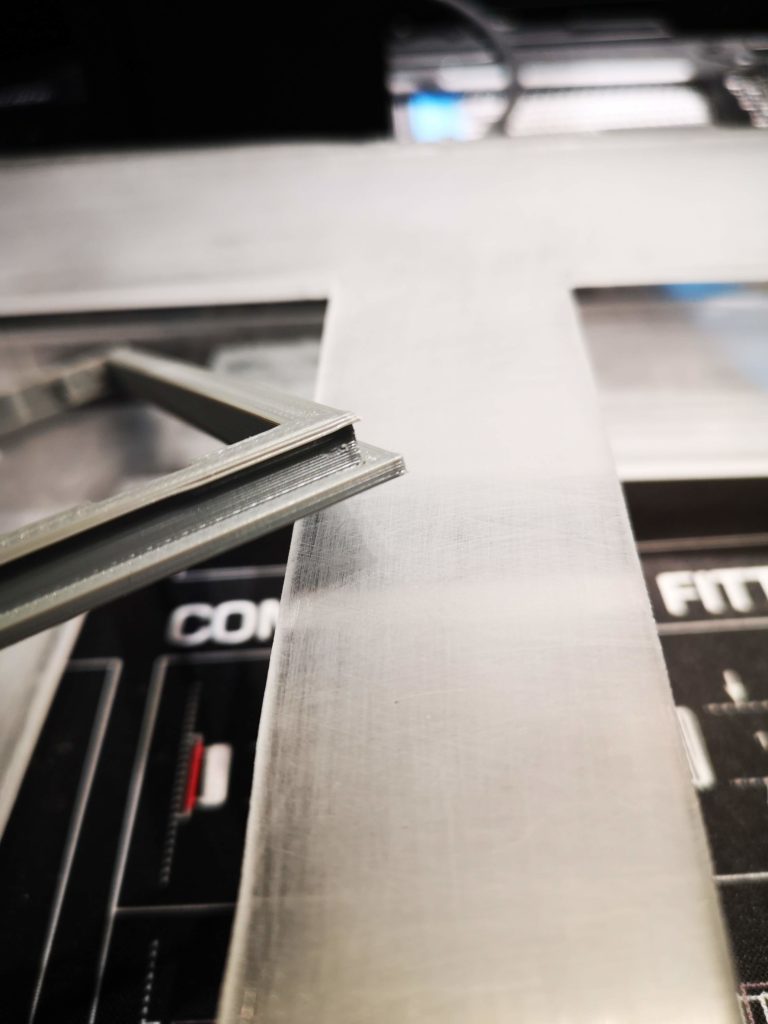

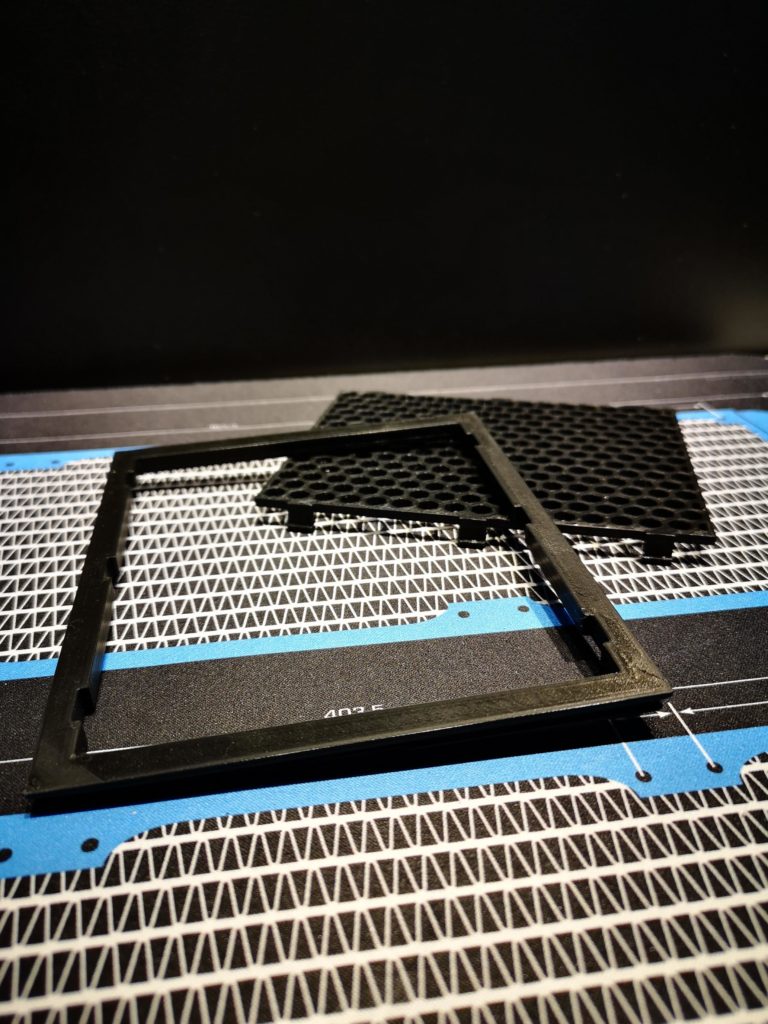

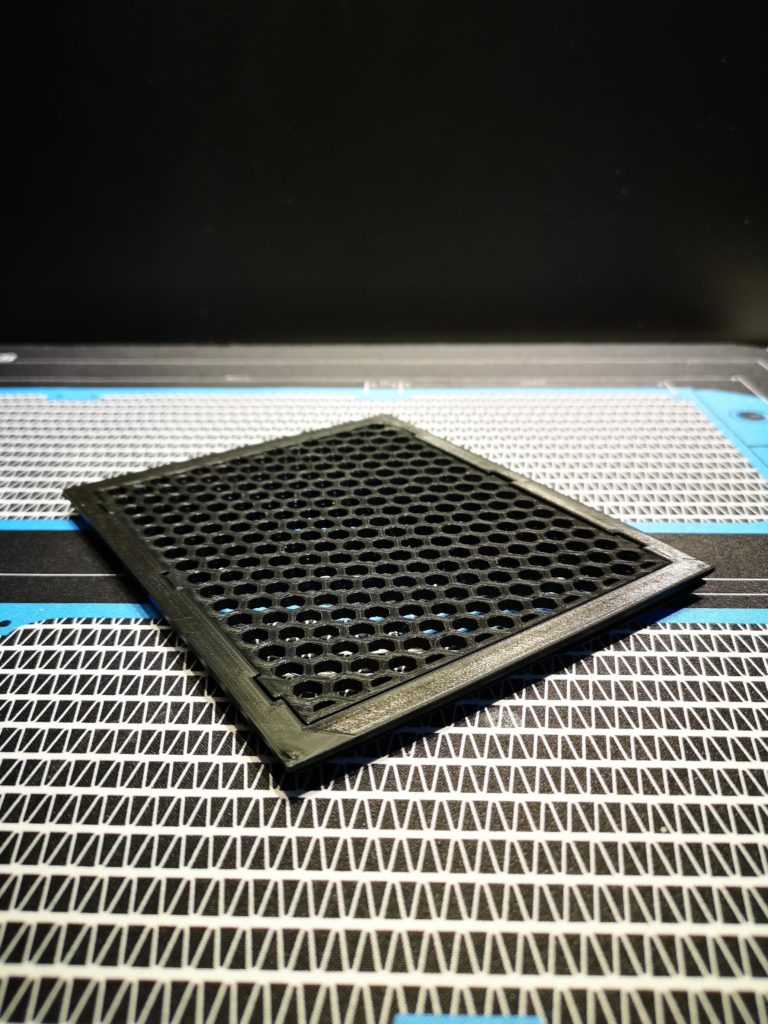

No, it’s not a window 😀 but almost. It’s the prototype design for the clip-in design for the air intake. Just added some structural elements to keep it sturdy while testing.

Fit’s perfectly (dimensions are a little of due to prototype printing profile (read speed printing). Will be much better with finished print. Happy with the solution.

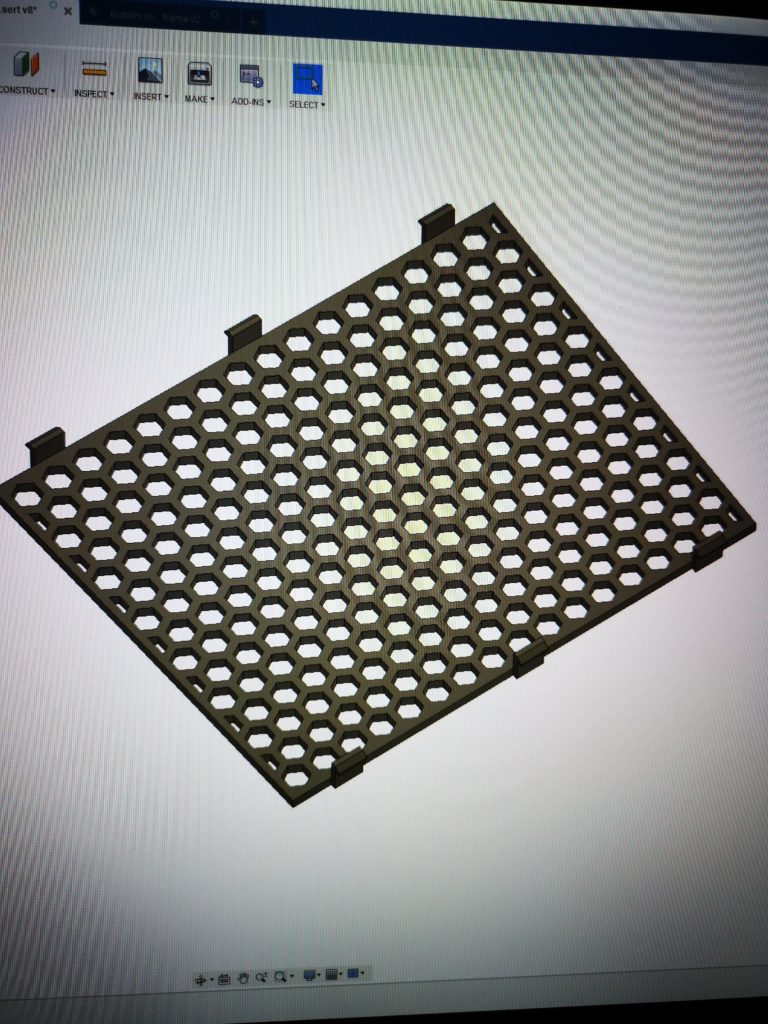

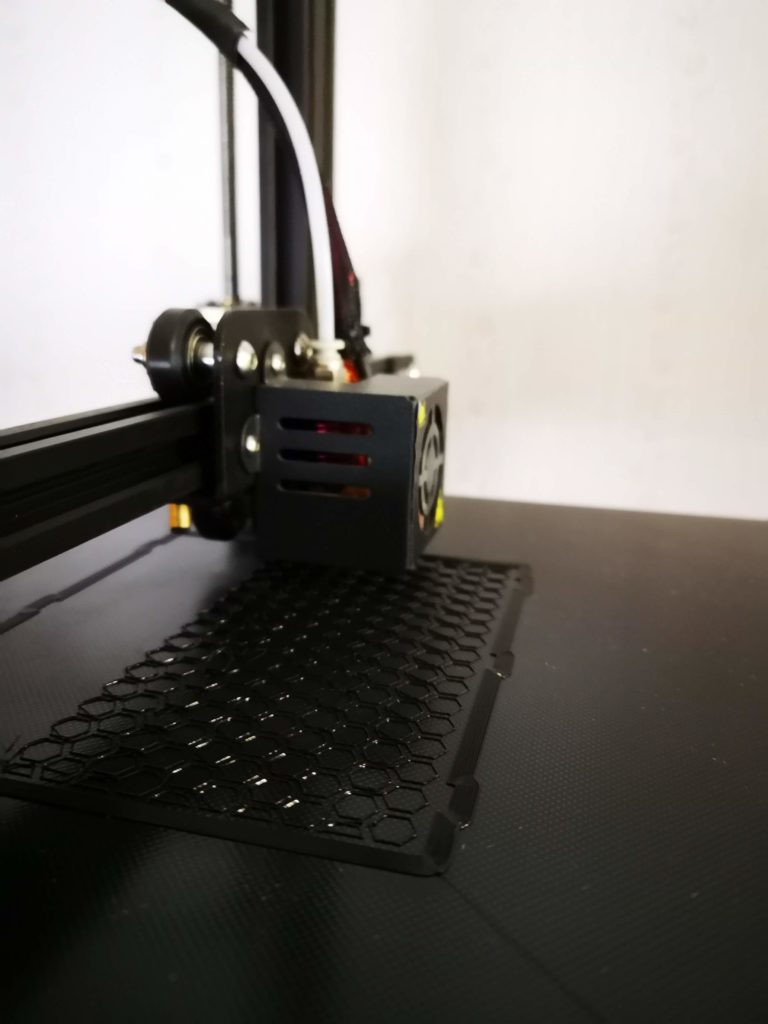

Spent some time testing out different designs and patterns, but decided for hexagons. Classic as well as fitting the design theme. Just hard to print…

That printer is just pooring out hexagons at a rapid speed. So happy 🙂 Creality CR-10S dialed in…

Not a bad view, not bad at all. Designed to print the fan intakes with the legs down. This forces the need for a fairly large support structure printed below. Extra filament, but almost double the time. Well worth it as the finished print will almost be flawless.

Nothing to complain about that…

Printed the frame in as well, but in end print profile and with Swedish high quality bio friendly plastic from add:north. Beautiful!

Perfect fit. Will add an air filter on the inside of the hexagon lid. It’s printed 3mm thinner than the frame to make room for this.

Reprinted my dual pump cover in add:north black as well. Just some light sanding and some paint and it should looks perfect.

With the end print profile, the fit is just perfect. Very happy with the result and well worth the design time in Fusion and prints.